by {0}

by {0}

Total floorspace (11,344㎡)

Total floorspace (11,344㎡) Annual export US $8,280,000

Annual export US $8,280,000 Offline trade shows attended(2times)

Offline trade shows attended(2times) Registered trademarks (5)

Registered trademarks (5)

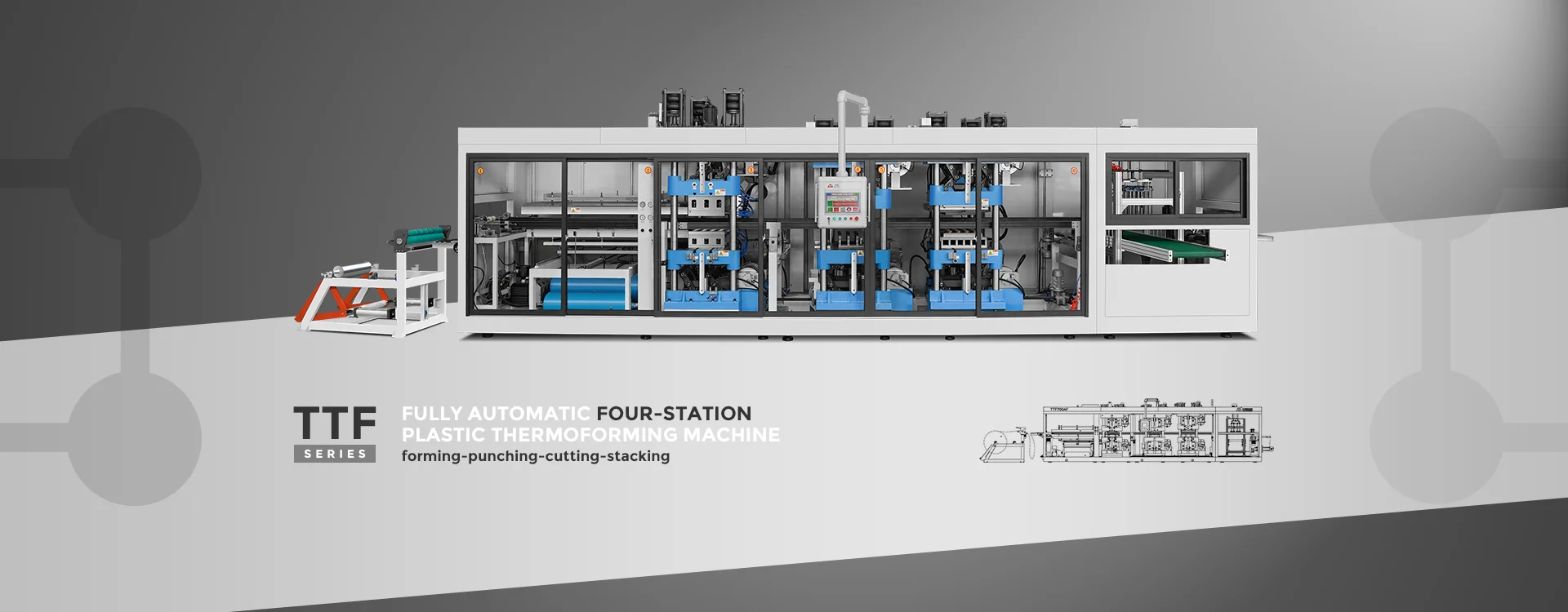

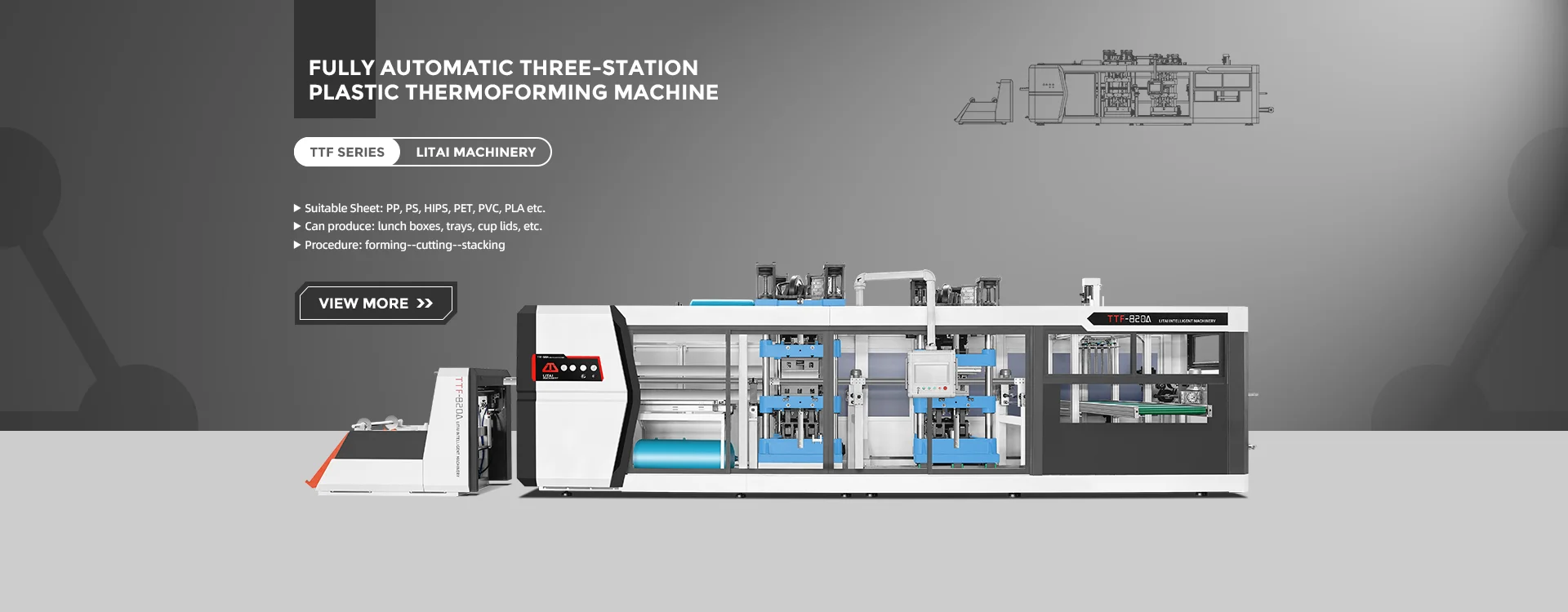

Let's make a brife introduce about our TTF-700AF four station plastic theremoforming machine. First, compared with previous normal vacuum machine, our TTF-700AF is a fully automatic plastic theremofroming machine which integrated sheet loading, sheet convey, heating, forming, cutting ,stacking and rewinding. Becuase of the fully automatic which brings high speed, more efficiency, lower human resouce cost (as vacuum theremofroming macine speed is around 8-10 cycles/min but our TTF-700AF can reach up to 30 cycles/min ). The working theory is a combination of pastive and negative pressure with assiting strenthing in mould by some nylon plugs. Which makes it have more powerful ability of making products. So it brings wider application just like big deep and more complicated botton. TTF-700AF is driven by full servo motor, which makes more precise, more efficient, lower noise, longer machine using time. TTF-700AF final products will have a widely used, such as food container, egg tray, seedling plate, plate, coffee lid etc.

Total floorspace (11,344㎡)

The data is from onsite check of the latest inspection report assessed by independent third parties

Annual export US $8,280,000

The data is from the latest inspection report assessed by independent third parties

Offline trade shows attended(2times)

Suppliers who have participated in offline trade shows, as assessed by independent third parties.

Registered trademarks (5)

The data is from the latest inspection report assessed by independent third parties

Total floorspace (11,344㎡)

The data is from onsite check of the latest inspection report assessed by independent third parties

Annual export US $8,280,000

The data is from the latest inspection report assessed by independent third parties

Offline trade shows attended(2times)

Suppliers who have participated in offline trade shows, as assessed by independent third parties.

Registered trademarks (5)

The data is from the latest inspection report assessed by independent third parties

- www.fkdmg.com

- www.fkdmg.com

Our products have obtained a number of invention patents and utility model patents, and our machines have passed CE and ISO 9001:2000 certifications. Our products are exported to more than 80 countries and regions such as the United States, South Korea, Turkey, Canada, Russia, Kuwait, Iran, Brazil, Chile, Bolivia, Saudi Arabia, Yemen, Peru, etc. Over the years, the company has always adhered to the service tenet of "customer first, sincere service", and welcomes new and old customers to cooperate and communicate.

In accordance with the requirements of ISO9001:2000 international quality standard system and CE certification system, Litai Machinery has established a complete, applicable and effective quality assurance system from product development and design, production and manufacturing to sales and service. All aspects of quality and work quality are under strict and effective monitoring.

Intertek

Intertek Verified onsite by world-leading inspection company, INTERTEK Group

Verified onsite by world-leading inspection company, INTERTEK Group